Sound Off Series: Why North America Got Trapped Into Using Inferior Dimming Technology

By Michael “MJ” Johnson, founding partner, Global Lighting & Controls | Sales and Marketing

If you’ve been in the lighting industry in North America for any length of time, you’ve probably heard people discussing (or arguing) why, in the U.S., 0-10V is our de facto dimming technology instead of DALI, as it is in Europe. Here are the common reasons you’ll hear:

• 0-10V is cheaper than DALI.

• DALI only goes up to 64 devices; our buildings are bigger than that.

• 0-10V is simpler to install.

• DALI is complicated and hard to program.

And so on…

Unfortunately, none of that is true! (And I am more than happy to debate that with you!)

The truth is, the main (some may say the only) reason DALI didn’t initially take off here in the U.S. is timing. In the late 1990s, two significant events happened in the world of lighting controls. Energy prices spiked in Europe, and GE introduced their Total Lighting Control (TLC) system.

Let’s talk about TLC first.

In those days, we didn’t have the state energy codes mandating lighting controls that we have now. The addition of lighting controls to a project was driven by common sense, not mandated by the government. Before TLC, the most common way of automatically controlling lighting was with a mechanical time clock and multi-pole contactors, assembled in the field. This solution was rarely used for indoor lighting because you couldn’t override the lighting after it was turned off without going into the electrical room (in the dark).

TLC changed all of this. TLC was a factory-assembled relay panel with GE’s rock-solid RR7 (later RR9) relays, a built-in digital time clock, and inputs for override switches. TLC was a hit! Now, what happens when a company introduces a game-changing product? That’s right, other companies come out with knock-offs. In the late ’90s and early 2000s, the major players in lighting control (other than GE) were Lutron, Wattstopper, LC&D, PCI, Douglas, and Nexlight. All six of these companies came out with relay panel-based systems designed to compete with TLC.

During the same timeframe in Europe, energy prices were spiking, and they were looking for ways to reduce energy consumption. However, they didn’t have one company with a game-changing product like we had here. Instead, 22 major companies got together, led by Philips and Siemens, and formed Activity Group DALI. DALI was the first open-standard communication protocol developed specifically for commercial lighting control. As an open standard, any manufacturer could produce products that used DALI. DALI allowed every fixture to be individually addressable, which is a major advantage over hard-wired 0-10V dimming.

So, in the U.S., we had multiple companies with relay panel systems, which soon included 0-10V outputs for dimming. While in Europe, they adopted a market based on lighting integrators, who could buy DALI devices from multiple manufacturers and were responsible for installing distributed lighting control systems.

So the question is: When DALI was introduced to the U.S. in 2001, why wasn’t it embraced by the major lighting control manufacturers of the day? After all, it was superior to 0-10V dimming. The answer was simple: Money! More specifically, R&D money. All of these companies had just developed their own proprietary systems, which included their own proprietary communication protocols. It was too much to expect them to just scrap what they had invested in just a few years earlier and embrace DALI.

How DALI Is Superior to 0-10V

0-10V is NOT a standard

Did you know that there is no set standard between manufacturers on what 0-10V means? The scale can vary greatly from one driver manufacturer to another. So, if you have two fixtures with the exact same characteristics, the only difference being that the drivers are from different manufacturers, there is almost a 100% chance that they will dim to different rates when given the same 0-10V command. With DALI, the fixtures are sent the exact same digital command. If a command is sent to the fixture to dim to 25%, all of the fixtures that receive the command will dim to exactly 25% of their lumen output, regardless of the manufacturer.

One-Way Communication

A 0-10V driver can only receive commands. Unless you are looking at the fixture being controlled, there is no way to know if that command was received or if the command was executed. If the fixture has malfunctioned or been damaged, the only way to tell is to visibly inspect the fixture.

DALI uses two-way communication. After sending a command to a DALI driver, the driver will first acknowledge that the command was received and then confirm that the command was executed. A DALI driver can also be programmed to alert you if there is a failure.

Ease of Installation

With 0-10V, you use two wires and daisy-chain those wires from fixture to fixture. All of the fixtures in a room or group have to be wired together. You typically use pink and gray wire, and you MUST land the same color wire on the same terminal on every fixture in the group! If the wires are crossed on even one fixture, the group will not work, and you will have to get back up on a ladder or lift and check each and every fixture to find the mistake.

DALI also allows you to daisy-chain just two wires from fixture to fixture, but unlike 0-10V, with DALI you can land either wire on either terminal, eliminating the potential for mistakes.

DALI Drivers/Systems Are Much More Expensive — MYTH

MYTH Busted!

A DALI system almost always costs less than a 0-10V system. Let’s look at the facts.

• Every major (and most minor) driver manufacturer makes both a 0-10V and DALI version of all of their drivers. These drivers typically are made in the same factory, and the component difference is so small there is almost no difference in the cost to manufacture.

• If there is a cost difference, it is due to the transportation of the driver, not because DALI is more expensive to produce. One of the biggest myths is the typical cost difference. I commonly hear anything from $20 to $30 difference per driver! But after a recent survey of three driver manufacturers, the average difference was around $7.

• So, you ask how is DALI cheaper if you just admitted that there can be a price difference on the drivers? With DALI, it’s all about the installed cost. For example, if you have six rooms to dim, with 0-10V you’ll need six individual 0-10V output devices, and you have to pull the two wires from each device to the room to be controlled. With DALI, you only need one output (for up to 64 fixtures to be controlled) and a single pair of wires that you daisy-chain in the easiest order between all of the fixtures. Because DALI is digital, you can group the fixtures via programming, not hard wire. So with DALI, there is a significant savings when it comes to control devices and wiring, not to mention labor. Now factor in places like the city of Chicago where all the wiring has to be in conduit!

Performance Issues

A 0-10V signal is just a voltage change from 0 to 10 volts. But like any voltage signal, it is subject to voltage drop. So if you have a long row of fixtures, like in a corridor, that are all connected to the same 0-10V output, the first fixture and the last fixture will dim to different levels. This is a very perceivable difference!

Multiple Networks

On a 0-10V system, the two wires are only used to send the dimming command. All other devices, like relays, switches, sensors, etc., have to be wired separately. With DALI, the two wires can be used to network all of the fixtures as well as the system components.

Additional Advantages Over 0-10V

• Simple wiring of control lines (no group formation, no polarity).

• Control of individual units (individual addressing) or groups (group addressing) is possible.

• Simultaneous control of all units is possible at any time (built-in initial operation function) through broadcast addressing.

• No interference of data communication is to be expected due to the simple data structure.

• Running power and signal in the same conduit is allowed.

• Control device status messages (lamp fault, etc.), (report options: all / by group / by unit).

• Automatic search of control devices.

• Logarithmic dimming behavior – matching the eye’s sensitivity.

• System with assigned intelligence (every unit contains, among other things, the following data: individual address, group assignment, lighting scene values, fading time, etc.).

• Operational tolerances of lamps can be stored as default values (for example, for the purpose of energy savings, maximum values can be set).

• Fading: adjustment of dim

• Identification of unit type

• Options for emergency lighting can be chosen (selection of specific ballasts, dimming level).

• No need to switch on/off the external relay for the mains voltage (this is done by internal electronic components).

DALI in North America Today

Once most people see the facts, they agree that a move from 0-10V to DALI over time is enviable. In fact, we are already seeing that move today. Two major changes are happening in our industry that are the catalysts driving the North American industry toward DALI.

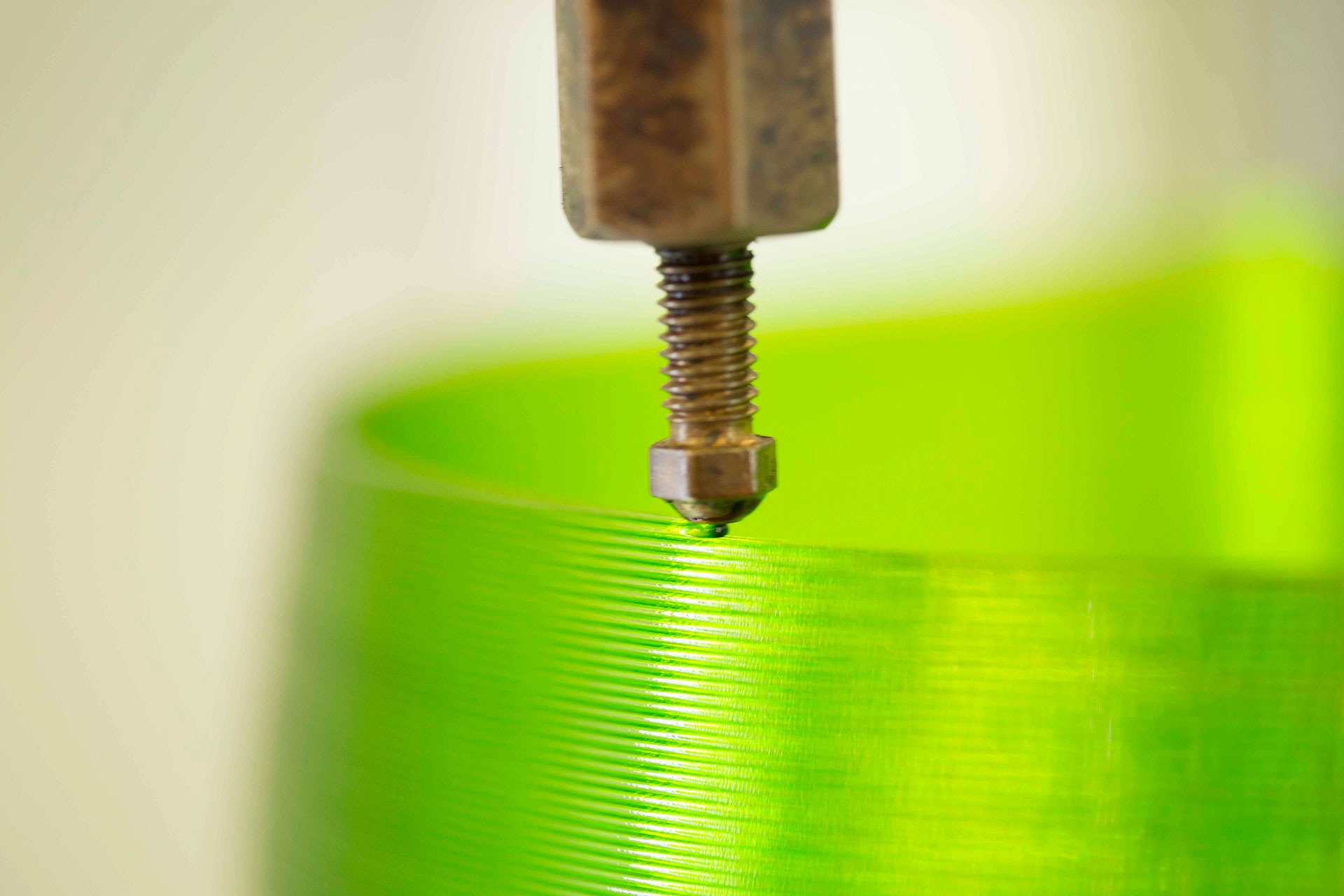

Human-Centric Lighting

White tunable fixtures used for human-centric (circadian) lighting are intended to continually change color temperature throughout the day, matching the current color temperature of the sun. When fixtures use a DALI driver (Type 8), you still use just two wires to connect the system to the fixture. The digital DALI command from the system controls both the intensity of the fixture and the color temperature. If you attempt to do the same scenario using 0-10V, you have to have two sets of two wires: one set for intensity, and one set for color temperature. But that isn’t the only problem. As mentioned above, there is no set standard when it comes to 0-10V, and that includes the control of color temperature.

Requirements for Addressable Fixtures

“We have the technology; we can rebuild it.” I’m paraphrasing and showing my age at the same time, but if we can easily and inexpensively individually control every light fixture in a building, why aren’t we? Common sense will tell you (as well as a lot of studies) that it saves more energy, increases employee satisfaction, makes spaces more marketable, and allows for easier re-purposing of spaces.

But as we all know, common sense is not always enough to move the market. So, here are a couple of things that have started to drive this trend.

Design Lights Consortium

The Design Lights Consortium has a program that certifies Networked Lighting Control (NLC) systems. One of the DLC’s requirements for systems is the ability to individually control lighting fixtures.

Future Energy Code Versions

Rumor has it that the next version of California’s Title 24 will require individually addressable fixtures in specific areas. And as we all know, once something is in Title 24, it won’t be long before we start to see similar requirements in other state energy codes.

Conclusion

The conclusion, well, that’s for each individual and the market to decide, but it just seems a bit backwards to me that the majority of the lighting in the world today is solid-state, and we are still trying to control it with an analog method that isn’t even a real standard.

________________________________________________________________________________________________

Editor’s Note: Do you have an opinion about a technology, trend, or industry challenge that you would like to share with a larger audience? Write down your thoughts (600-1,000 words) and email them to us for consideration in an upcoming Sound Off column.