Why Lumen Depreciation is Costlier Than You Think

By Cree Lighting

LEDs, like all light sources, lose light over time. The term used to describe this is sometimes referred to as lumen depreciation. In lighting design, understanding the rate of this decline over time can help determine the amount of light available at some point in the future. For a little historical perspective, the rate at which legacy HID lamps lost light over time occurred much faster compared to LEDs. In addition, the rate of decline for HID lamps was not influenced by product design, therefore rules were put in place and applied equally across all manufacturers products as it related to lumen depreciation.

LED luminaires are different. First, LED luminaires are designed to lose light at a much slower rate than the legacy products they were designed to replace – eliminating costly re-lamping events. Second, not all LEDs deliver the same performance as it relates to lumen depreciation; therefore, if manufacturers are using different LEDs, you’ll likely get different results. In addition, an LED’s performance will also be influenced by product design. The amount of current a manufacturer decides to apply to the LED, as well as how the product is designed to thermally manage the temperature at the LED itself, will also influence light loss over time. Lastly, it should be noted that lumen depreciation data is not a statement on product life. Many misinterpret statements like L70 to reflect product life, but it does not. L70 statements simply predict when the LED will be at 70% of its initial light output or 30% lumen depreciation, under the conditions for that product. It makes absolutely no claims on the expected “life” of the overall luminaire.

When it comes to properly applying lumen depreciation data to LED luminaires, there are some common mistakes. These include ignoring that lumen depreciation occurs and/or assuming that it occurs at the same rate across all products. In addition, many fail to consider and define the useful or expected application life of their design. Since lumen depreciation occurs over time, defining a useful or expected application life is critical to selecting a corresponding lumen depreciation value based on your defined application life. Lastly, it’s critical to define your lighting goals and objectives, helping ensure that when your lumen depreciation value is applied to your design, you are confident that your lighting system will continue to produce enough light to meet the illumination requirements of your application over its entire designed life.

Let’s try to make this more understandable through an example.

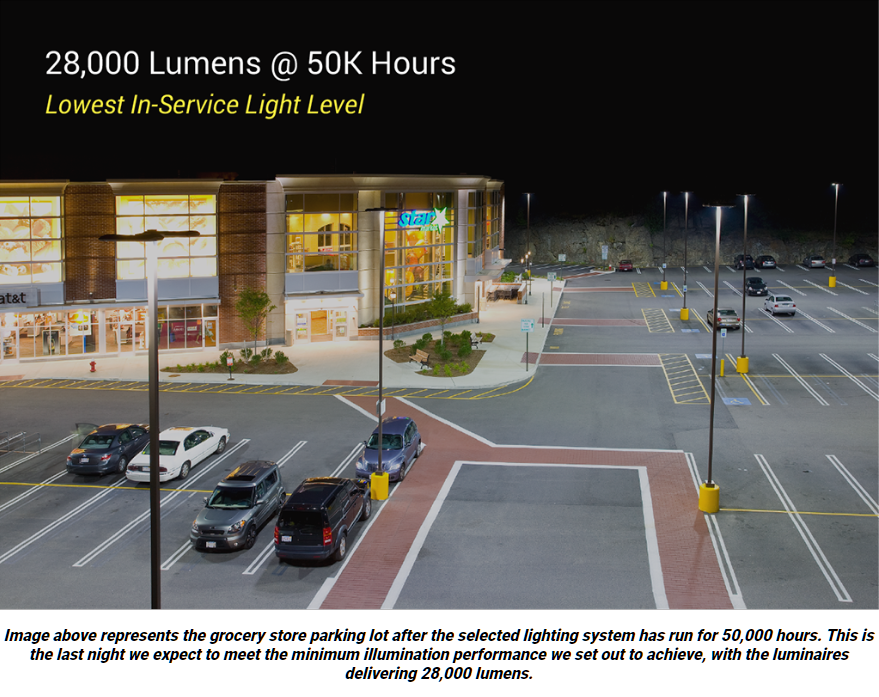

Assume we are asked to design and select a luminaire for use in a grocery store parking lot. After speaking with the owner and going through the lighting design process, we determine that 28,000 lumens are required to meet the minimum illumination performance the owner requires. Since this is the minimum lumens required to do the job, we need to account for light loss over time for whatever product we select to ensure we can meet the owner’s lighting requirements beyond the first night of the installation. We must also define the expected application life, as the lumen depreciation value we select will be based at some point in time in the future. In our example, we’ll assume an expected application life of 50,000 hours (11.4 years based on 12 hours of use each night).

Application assumptions:

Now let’s assume we’ve narrowed the potential products for use down to two luminaires.

Luminaire A

Lumen Maintenance Factor (LMF) = 0.70 @ 50,000 hours (30% light loss from initial @ 50K hours)

Required initial lumens based on 0.70 LMF = 40,000 lumens (40,000 X 0.70 = 28,000)

Luminaire B

Lumen Maintenance Factor = 0.95 @ 50,000 hours (5% light loss from initial @ 50K hours)

Required initial lumens based on 0.95 LMF = 29,474 lumens (29,474 X 0.95 = 28,000)

What’s the value of significantly reduced lumen depreciation? You’ll notice that we are expecting both Luminaire A and Luminaire B to end up at the same place (~28,000 lumens). So, what’s the difference? Because Luminaire B has much less lumen depreciation over time, its initial light levels are much closer to the lowest in-service light levels delivered at 50,000 hours. Luminaire A requires significantly more initial lumens, 40,000 lumens in our example versus only 29,474 initial lumens required of the Luminaire B product (that’s more than 35% more initial lumens from the Luminaire A product).

The economic implication is a higher lumen, higher cost product (Luminaire A, 40,000 lumens), that consumes more energy, further increasing the total cost of ownership. From an environmental standpoint, more light or significantly overlighting the space introduces increased light pollution into the environment and all the negative consequences that brings. So, while Luminaire A significantly overlights the space for much of its application life, Luminaire B eliminates significant overlighting for the entirety of the application. In addition, if you consider efficacy or Lumens Per Watt (LPW) at 50,000 hours, you would find that Luminaire B would also be much more energy efficient at 50,000 hours compared to Luminaire A.

So, the next time you’re tempted to treat lumen depreciation the same for ALL LED luminaires, resist the urge. Not only will it cost you money, but it will also compromise some of the environmental benefits that LED lighting can deliver to your application.

Note: Images shown are for reference only to help illustrate lumen depreciation over time.

Source: Why Lumen Depreciation is Costlier Than You Think – Cree Lighting