Value Engineering: How You React as a Lighting Leader is Key for 2025

When I started in electrical distribution 25 years ago at Crescent Electric Supply one of the most mystifying items to understand was lighting. The concept of the channel, lighting reps, manufacturers, overage, and value engineering was frankly overwhelming when you first get started in the channel. Over the years you pick up more knowledge and learn how to do a takeoff, a lighting design with photometrics, and work with the contractor and the specifying engineer.

What I learned over the past 25 years is the one constant to winning for the manufacturer/rep, distributor, and contractor in lighting is understanding once you have the job how to navigate the inevitable – Value Engineering.

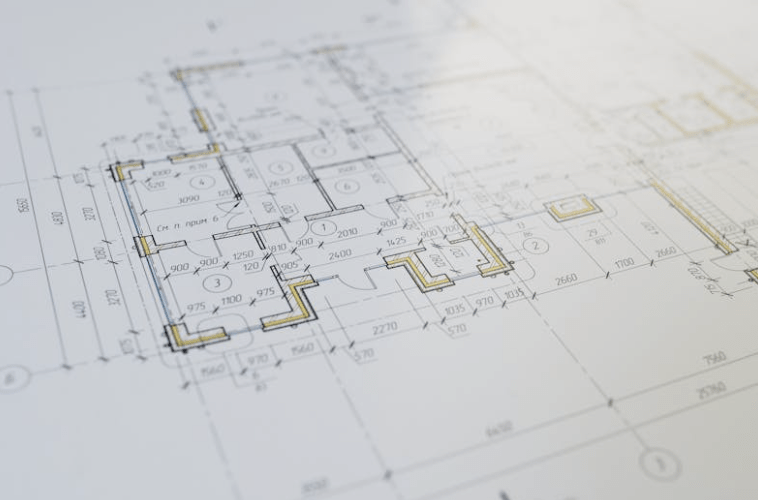

I thought it would be fun to do a little review of why value engineering is so important in lighting. Much of it ties to how a project comes together in stages (new construction). The Construction Specifications Institute Master format for decades was deployed in 16 Sections (plans and blueprints):

- Division 01 — General Requirement

- Division 02 — Site Works

- Division 03 — Concrete

- Division 04 — Masonry

- Division 05 — Metals

- Division 06 — Wood and Plastics

- Division 07 — Thermal and Moisture Protection

- Division 08 — Doors and Windows

- Division 09 — Finishes

- Division 10 — Specialties

- Division 11 — Equipment

- Division 12 — Furnishings

- Division 13 — Special Construction

- Division 14 — Conveying Systems

- Division 15 — Mechanical/Plumbing

- Division 16 — Electrical – Where lighting lives and gets installed

*Please note these 16 sections have now been broken up into 50 sections today, but for brevity purposes of the article. I stayed with the original 16 macro sections as it is easier to follow.

If you think about it visually – The site work is first, then concrete, building shell/roof, and so on. Electrical plans are last (Division 16) for a practical reason. The electrical is the last division because it is the last major part of a project, and of electrical lighting is the very last major installation in a project.

My contractor father often used to joke that there are only two kinds of construction projects “Those that are behind schedule, and those that are over budget.” He proudly said he was an expert at working on both of types of projects.

So, when a project is one of the two – the over budget kind, the budget cutting attempt often occurs in the last part of the project which is electrical.

Inside the electrical division the “Gear” the big gray power boxes are installed first and because of the voltage and danger are highly specced/engineered. So, value engineering is not as prevalent or practical on Gear as if you make a mistake on that portion it is life threatening. That leaves lighting as the main target for Value Engineering in most new construction projects for those projects that are “over budget”.

Lighting Designer Value Engineering

As a lighting designer you put in hours of work into your design. You want your specs and design to be followed as need get the “right footcandles to the right place”. You also aesthetically have a look and feel for your fixture choices that for many projects are crucial. You want in short – the right light with the right look. You also often have thought out the potential value engineering hierarchy of products which ones you have hard specced vs. which ones if Value Engineering is needed you might accept a lower cost as equal for. No matter the project, you do not want to sacrifice quality or performance.

Manufacturer/Lighting Agent Value Engineering

For the manufacturer getting your products specified is a lot of work and when you get them specified getting Value Engineered out is a threat. You fight the fight to your specified products and not get substituted as “an equal” for anther brand. If you can not avoid that move towards a lower cost solution you want it to be your brand. E.g. having to move from your architectural “best” brand to your “good brand”. This is an area where the manufacturer and lighting agent working with the end contractor and distributor is crucial and a large part of their value proposition for the channel.

Distributor Value Engineering

The distributors’ role varies by market and by project. This “depends “ situation is tied to how involved the distributor with the end contractor, manufacturer, and rep. The distributor involvement level on value engineering is very dependent on their relationships with each party, their reputation and support team, and their ability to get the right product to the right place in time.

Contractor Value Engineering

The electrical contractor is often under intense pressure near the end of the job to get it done quickly and save us much on product cost as possible. They live in this Division 16 world being the last installation and the difference between a profitable and unprofitable job is often razor thin. The relationship of all parties from the specifier/engineer, manufacturer and their rep, and the distributor is vital to ensure when Value Engineering is needed. These parties must come up with solutions and compromises that work for each other.

So, what are the takeaways for manufacturers

The manufacturers and brands that win more often take the long view on lighting and value engineering because if you blow up a project with a contractor they tend to never forget that black eye they took from you. Your brand is your most valuable asset and working with all parties when Value Engineering is needed is a crucial win or lose point.

How can your brand and team help when Cost Savings are required without sacrificing Quality, Performance, Efficacy, Reliability, Optics and Aesthetics is the name of the game?

As a distributor leader I would recommend the following for simple concept for every manufacturer to consider-

When you win the specification, the work is sometimes just starting. The manufacturers and lighting agents that win and hold their product position most often are always communicating the “Why”.

Why my products are the choice, and why if you substitute my specified products it would be mistake?

You have played offense and got the specifying engineer/lighting design to get specced and scored the touchdown. Once that is done and the project is won, you are kicking the ball off and now playing defense.

The manufacturers that consistently win more in my career experience most often are constantly communicating “Why” they deliver the best quality, aesthetics, performance, optics and efficacy to all parties.

They use email, advertising, direct calls, relationship building, and training and are relentless and repetitive on Why they are the only choice. They consistently and relentlessly drive the value of their brand over the competition and win more often.

The golden rule is the more often you communicate your value to all parties the more often you win.

As always, we appreciate your comments and suggestions.

About the Author

John Gunderson is a senior distributor leader with more than 25+ years of experience leading category management, sales, marketing, pricing, analytics and e-business with companies such as Crescent Electric Supply Company, HD Supply Power Solutions, White Cap Construction Supply, Anixter/WESCO, Modern Distribution Management, Dorn Group and EIS-Inc. He writes for industry publications such as MDM, Electrical and HVACR trends. You can reach John at jgunderson@uslightingtrends.com