LED Lighting Retrofit Success: Simple Solutions for Complex Needs

As an Electrical Contractor in the lighting industry, Guarantee Electrical focuses on delivering industry-leading solutions, ultimately leading to successful projects for our clients. As an Energy Solutions Project Manager, my focus is on providing energy-efficient lighting solutions for commercial and industrial clients. From exterior and interior lighting to new LED fixtures, lamps, and lighting controls, we can address any lighting needs our clients may have. In my fourth article here, I’m going to highlight a “True LED Lighting Retrofit” success story from a recent project we completed, illustrating that sometimes the simplest solution is the best option for our clients.

Defining the Project’s Focus

During my process with potential clients, I always start by asking the same question: “Is this a true lighting project or an energy project?” You might wonder what that means. Essentially, are we trying to solve a problem with the lighting in some way, or are we aiming to reduce energy usage through a lighting upgrade? The answer to this question helps us design a successful project tailored to the customer’s needs.

Initial Assessment and Proposal

In February, our Solar division’s business development manager, William Hatch, met with Facilities Manager Rob Weber at the Sheet Metal Union Local 36 facility in St. Louis, MO, to discuss a potential solar energy project. During their initial meeting, William noticed that the facility was still using old fluorescent lighting. He recommended that Rob speak to one of our energy solutions experts about a possible LED lighting upgrade to ensure any future solar energy projects would be as successful as possible. That’s where I entered the conversation to support this effort.

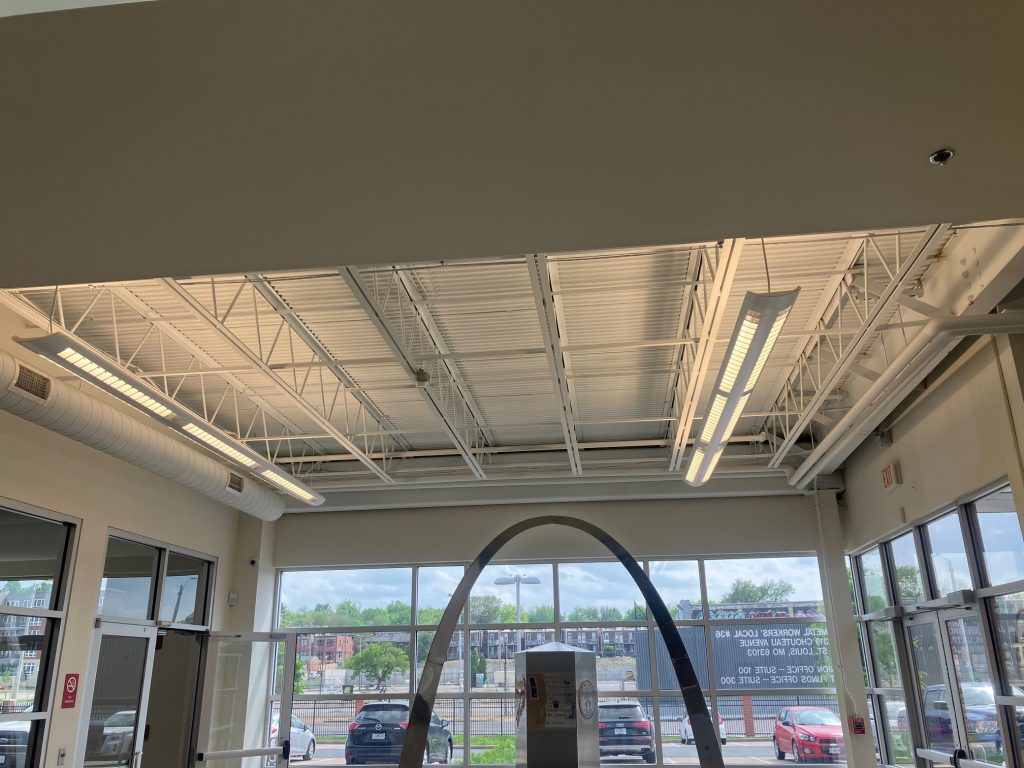

Within a couple of days, I met with Rob at the facility to review their lighting needs and options moving forward. He informed me that the 100 000-square-foot facility, built in 2012, was St. Louis’ highest-rated LEED structure, and Guarantee Electrical had acted as the electrical contractor for it. It was great to hear they were a returning customer! I quickly identified that all the existing lighting on-site was high-quality architectural spec-grade fixtures, leading us to a simple LED retrofit. Rob provided the original building prints to determine the counts needed for our proposal. We decided to maintain the 3500K color temperature for the new LED lighting to ensure consistency.

The Turnkey Solution

We provided Rob with a complete turnkey LED retrofit project proposal, including new LED lamps, emergency backups, full installation and wiring, and an Ameren MO utility incentive rebate to help offset the initial investment. The proposal offered an estimated 2.5-year payback period, annual energy savings of 262,000 kWh, annual energy cost savings of over $31,000, annual carbon reduction of 217 tons of CO2, and a rebate covering approximately 25% of the total project cost. Additionally, we ensured uniform color temperatures and a brighter environment that would blend naturally with the facility’s lighting. These impressive figures made for a quick and easy decision for Rob and his team, so we were off and running!

Choosing the Right Partners

Choosing the right partner for the project was essential. We decided to work with Keystone Technologies for their high-quality service and industry-leading LED lighting options. I contacted my Keystone representative, Rich Keuss, to begin writing the project specifications, ensuring we knew exactly which solutions we would be using. The project scope was simple, requiring only five part numbers to complete our bill of materials. We selected the following products from Keystone:

- Type-B Bypass 25W LED T5HO 3500K with 136 lumens per watt

- Type-B Bypass 10.5W LED T8 3500K with 157 lumens per watt

- Type-B Bypass 8W 2-Pin LED 3500K with 113 lumens per watt

- Type-A Smart Drive 9W 4-Pin LED 3500K with 100 lumens per watt

- Emergency LED Backup 5W with 90-minute operation (compatible with all lamps)

When we placed our order, Keystone had all the materials in stock at their Kansas City warehouse, allowing us to receive the product within 48 hours. This rapid delivery enabled us to start the project on-site promptly. We worked as a team with Keystone Technologies and our distribution partner, Ryan Meyer with Holt Electrical Supply, whose location was only three miles from the site, to manage pricing and delivery.

Project Completion and Results

The project was completed on time within a six-week period, without interfering with daily operations and classes at the facility, and ahead of a major upcoming conference for the Sheet Metal workers. Our team of lighting maintenance professionals enjoyed installing the Keystone Technologies items, as they were straightforward and quick to complete, with no issues along the way. Our client was extremely happy with the project results, as the improved lighting enhanced the facility experience for everyone. With the lighting properly taken care of, the client can now focus on other maintenance items, maintaining their LEED-certified building’s peak efficiency without being distracted by frequent lighting issues.

Key Takeaways and Lessons Learned

The key takeaway from this project experience is that the simplest solution often yields the best results. We allowed the facility’s needs to guide us to the most efficient and effective solution, resulting in a successful project for all parties involved. The lesson learned here is to keep it simple and choose the best partners for the client’s project.

Guarantee Electrical is excited to continue our partnership with Sheet Metal Local 36 St. Louis, supporting them in sustaining their sustainability efforts. We would love to hear from readers about their positive or negative experiences with LED retrofit projects over the years.

Who is Andrew Boerschig?

Andrew is a standout project manager at Guarantee Electrical in St. Louis, recognized for delivering innovative energy solutions across the nation. His journey, illuminated through a causal LinkedIn story, showcases the critical yet often overlooked role of electrical contractors in the lighting industry. Without a contractor, no project gets completed hence the challenges and value, that a contractor can bring to an end-user and to specifiers. Their challenges, and partnerships with distributors, manufacturer representatives / lighting agents, and manufacturers are not discussed. Here is his third article.

- LinkedIn Profile – Andrew Boerschig (Problem Solver) Pure Energy – Storyteller | LinkedIn

- Guarantee Electrical – Guarantee Electrical Company | Electrical Contractor | St. Louis, MO | (geco.com)

- Guarantee Electrical – Energy Solutions – Lighting – Lighting | Guarantee Electrical Company (geco.com)

Transforming Efficiency: Sheet Metal Workers Embrace LED Lighting Solutions – US Lighting Trends

Article Links:

- SMART – Sheet Metal Workers SMART Local Union No. 36 (sheetmetal36.org)

- Keystone Technologies | Light Made Easy | Since 1945

- DirectDrive LED T8 Ballast Bypass | T5 | Keystone Tech

- SmartSafe | LED Emergency Battery Backup | Keystone Tech

- DirectDrive | 2-Pin LED Bulb | Keystone Technologies

- HOLT Electrical Supply – The STL area’s favorite supply guys.

- Guarantee Electrical Company | Electrical Contractor | St. Louis, MO | (geco.com)

- Lighting | Guarantee Electrical Company (geco.com)

- Solar | Guarantee Electrical Company (geco.com)