Sheet Metal Workers Embrace LED Lighting Solutions – Fluorescent Challenge

Replacement of legacy lighting with LED lamps helps building shine

When Sheet Metal Workers’ Local 36 St. Louis headquarters opened in 2012, it was a model of sustainability and energy efficiency. The 100,000-square-foot training facility included solar panels on the roof, renewable interior materials, and a Crestron lighting control system. It was St. Louis’ highest-rated LEED structure. Its lighting, however, was provided by fluorescent tubes. And that became an issue.

The Challenge

Ten years ago, fluorescent was a logical decision: LED was still an emerging and relatively unproven technology. But the fluorescents, dependent on ballasts, tended to burn out, said Rob Weber, the building’s facilities manager.

“A lot of the lights are on motion sensors and timers, and they set the timers as short as possible. In the high traffic areas that doesn’t work very well with fluorescent lights on ballasts, so we had a lot of ballasts going out.”

Initially, Weber simply replaced or rewired the affected fixtures to bypass the ballast. That had its own drawbacks, he noted. The updates created a patchwork of different CCT outputs with the original lamps, and negatively affected the working and training atmosphere for the occupants.

“The lighting was getting uneven,”

The Solution

So when the opportunity arose to redo the whole building with LED, he jumped at it.

The impetus was a discussion of upgrading the building’s solar array. A solar rep for contractor Guarantee Electrical Company, which had handled the electrical and lighting for the project in 2012, met with Weber and noted that the fluorescent lighting negated the potential savings of replacing and adding solar panels. Turning to LED and going with ballast-bypass UL Type B tubes was the logical move, said Andrew Boerschig, project manager with Guarantee Electrical.

“Being end-user driven, Keystone has the most encompassing product availability,” he said. “I can do both fixtures and lamps, interior and exterior, all through the same line.”

“We walked the facility and used the existing plans as a jumping-off point,” Boerschig recalled. “All of the fixtures were in pretty good shape, so it was truly just a LED retrofit project.”

Weber added that the timing was right. Ameren, the local power company, has a rebate program for LED lighting upgrades, and the project was a perfect fit.

“The present lighting is going away anyway, and while we could do it now and get the rebate from Ameren for them to pay a quarter of it, it made financial sense to just do it and be done with it,” he said.

Keystone was the preferred partner for the plan, said Boerschig. Fast shipping from Keystone’s Kansas City warehouse meant Guarantee had the product in 48 hours, and the wide range of lamps made inventory selection a snap.

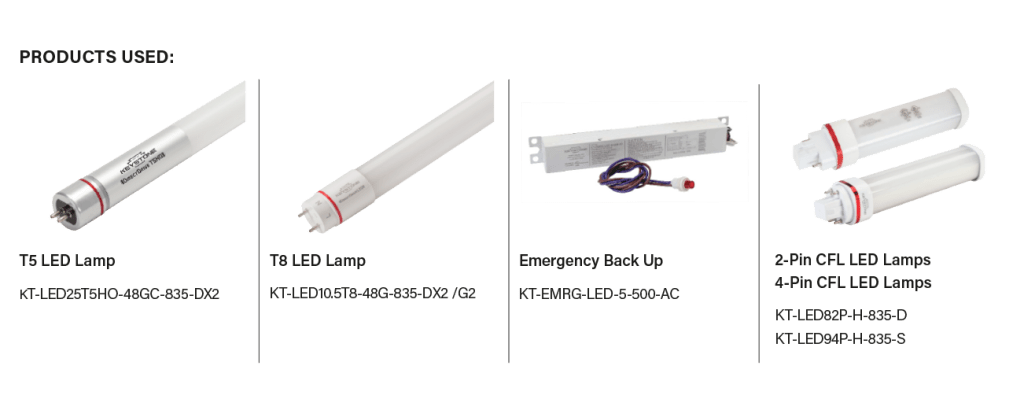

For Sheet Metal Local 36, Boerschig kept it simple. For most of the lighting, he opted for a combination of 25W 4-foot T5 and 10.5W 4-foot T8 UL Type B LED lamps to eliminate ballasts, mindful of them as a failure point. He stuck with UL Type A 4-pin lamps for decorative fixtures with unique components to avoid compatibility issues, though he expects those will be changed to ballast-bypass lighting in the coming years. In addition, Boerschig chose lamps with a dedicated 3500K CCT to maintain a consistent lighting atmosphere agreeable to staffers and visitors.

All Keystone products came through St. Louis-based distributor Holt Electrical Supply.

Installation went quickly. Even with rewiring, the job took about six weeks—on time, without interfering with work and classes at the facility, and ahead of a major conference for the sheet metal workers.

“We hit a home run, and the timing was perfect,” said Boerschig.

The Results

- Ameren, the local power company, provided a $20,064 rebate for the retrofit – almost 25% of the overall project cost

- The project will pay for itself in just 2 1/2 years and same more than 262,200kWh of electricity

- Even with a similar CCT to the legacy lighting, the overall environment feels brighter and meshes better with the natural light. There is a color difference, especially in the shop area.

Local 36’s Weber has commended the outcomes, noting that the new lighting has improved visibility, enhancing the facility’s environment for both employees and training purposes. With the lighting issue resolved, he can now concentrate on additional maintenance tasks, ensuring the LEED-certified building operates at optimal efficiency, without the distraction of failing ballasts.

Boerschig is extremely satisfied with the project’s success. He values Keystone’s reliability and customer service. “The assurance that everything will function correctly adds a level of legitimacy,” he remarked. “Keystone’s reputation as a dependable partner and our collaborative efforts guarantee the entire project’s high quality.”

More on Keystone products here