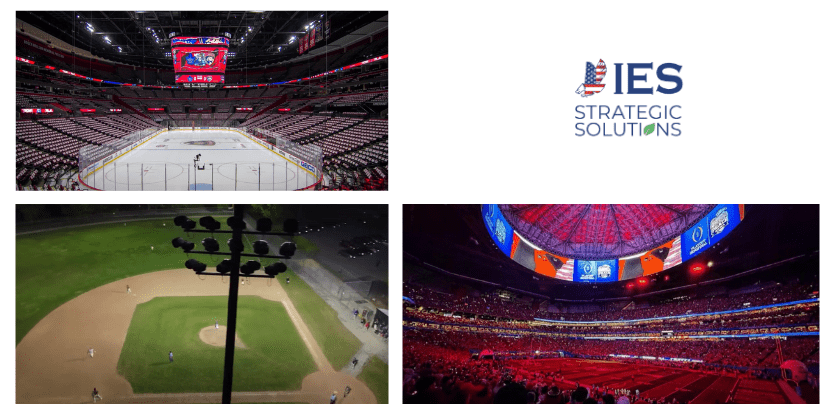

Is Sports Lighting the Next Frontier? IES’ Strategic Solutions Carves Out a Lucrative Niche

By Linda Longo

If seizing opportunity were a sport, Independent Electric Supply’s (IES) Strategic Solutions team headed by industry veterans Mike Berube, VP/Sales, and Ed Colombo, Senior Sales, would be All-stars. Together, with support from their team of six, they are dominating the category of sports lighting for municipalities and schools in New England.

Berube, a licensed electrician with 15 years of distribution experience as well as years spent as an independent lighting agent, and Colombo, who has 40+ years as an independent representative with expertise in sports lighting, are leveraging their combined knowledge to expand IES’ business in this under-represented niche while providing local communities with a new revenue stream.

I recently sat down with them to learn about the opportunities that exist for lighting professionals when it comes to sports lighting.

First, some background: over the past 30 years, family-owned IES has gone from a single location with one truck and a few employees to five locations across Massachusetts and New Hampshire, 100+ employees, a fleet of trucks, and a 100,000-sq.-ft. distribution center. (You can learn more about the company here). Approximately 18 months ago, Berube and Colombo were brought in to spearhead its new Strategic Solutions department to further expand the company’s capabilities.

Linda Longo: Does the fact that sports lighting has gotten sophisticated make your job harder or easier?

Mike Berube: It makes it easier for us that it’s more sophisticated because, for the most part, we’re leading the market right now. As the technology that used to be there (metal halide) is starting to be phased out, communities are looking for options. For years, those major brands [using metal halide] encompassed 90% of that marketshare. We’ve been able to be successful over the past couple of years by using LED and integrated controls to bring the dynamic lighting that kids are seeing on TV in the NFL and Major League Baseball into the municipal space. That technology is available, but typically no one is showing it to customers — and that’s where we started leveraging that growth.

LL: But doesn’t that add a lot more cost to a project?

MB: Usually it adds about $15,000 to the project cost, but with the utility incentives that we leverage right now, we have been getting that covered, so our customers’ out-of-pocket cost is minimal.

LL: Do you ever have a situation where a school or town does not want the lighting to be complex and just wants simple on/off?

EC: We do. I had one the other day with three or four Little League fields and they just wanted on/off. All of the fixtures we use come with nodes, so if they want to use controls in the future, they can just add that box later on. It’s really not a big expense.

MB: When we’re working with these communities, we’re looking to minimize their capital expense. We’ll work with a utility in that space and try to come up with a custom incentive. The utilities have traditionally not incentivized a lot of these fields because the base line for them was pre-Title IX and they didn’t update their sports standards.

LL: How does Title IX factor in?

MB: Once Title IX opened up [equality in sports], it doubled the usage hours of sports fields. Prior to Title IX, a field’s baseline hours were around 800 a year, and it didn’t really meet the usage for a utility incentive. Fields would typically be used for varsity men’s sports and JV, but now they’re used by youth, men’s and women’s sports, varsity, and JV — plus communities are using these fields for non-sporting activities such as concerts and charity walks.

EC: Another thing that expanded the sports lighting category was COVID. More people wanted to be outside, and there were requests for more fields. A baseball complex that used to be for the town league will now have teams coming in from all over because there are not enough fields available. Just the other day I went to a community that had four or five fields, but no light fixtures. They told me, “We have teams that want to lease our fields, but we need lights.”

LL: So, adding lighting can actually generate income for a town?

MB: Yes, this is a revenue generation opportunity for the municipalities — you can hold sports clinics and camps year-round. In New England, we’re seeing traditional grass fields being changed over to artificial turf. Once they put down turf, they can triple the usage per year because there is no more grass damage. If a community invests in turf, adding lights just makes sense.

LL: Do you approach municipalities, or do they come to you?

MB: We are strategically proactive in this space. Typical communities will reach out to regional engineering firms and say, “We want to do our lights, can you come up with a plan for us?” Then it would take 12-18 months to come to fruition as far as budgets go. Approvals from that point would take another six months, so a typical sports lighting project through traditional means would take 24-36 months.

[With IES’ wide array of services], if I have a customer who’s interested in sports lighting, our turnaround on design is roughly two weeks. We have a team that does layouts, Ed goes out to the field and does measurements on the poles, we do calculations for the photometrics — and all of that is at no cost. Where that customer might have paid an engineering firm $60,000 to put a design together that takes years, we are done with the design in two weeks and from there we leverage and negotiate utility incentives, navigate all refinancing options, and it’s up to the customer whether they want to move forward. At that point, nothing has been out of pocket for them.

We also talk to buying groups like Sourcewell, which has a division for Parks, Recreation and Athletics. We talk athletic directors in New England just to educate them — especially on players’ safety. When you start looking into sports lighting, there are a lot of nuances. For example, in a soccer game if a player kicks a soccer ball up in the air, you [visually] lose that ball under traditional lighting and it can come down and hit someone in the face. There are certain player safety issues in each sport; soccer is a little more fast-paced on the field than football, so when that ball goes up, you need to make sure you’re hitting those horizontal and vertical footcandles. A lot of folks who don’t pay attention to the details of each sport will just put a floodlight up.

LL: What are some other unique concerns involving sports lighting?

MB: We sit with the owners to discuss the field’s usage, and we work with engineering firms and soil sample engineers regarding pole heights and EPA wind loads. For retrofits, our concern is weight. Can that existing pole handle the weight of what’s going up versus what’s there. Those are areas where you have to know what you’re looking into, which is why we align ourselves with Cooper Lighting and their Ephesus system, Spring Lighting Group’s (SLG) full system, and Jademar, which has great optics and controls that point the light onto the field without affecting any houses around it. Depending on the application, each manufacturer has something a little different.

ED: Lamp light, optics, and spill light — all of that is taken into consideration. If we’re out in the middle of nowhere and there are no houses, we don’t have to worry; but we’ve done a couple of fields in the middle of a neighborhood and you have to be careful. When retrofitting, there are a lot of calculations, such as measuring the girth of the existing pole and the height. We might have to put on new brackets or utilize the existing brackets with clamps; there are a lot of options.

Right now, retrofit is a big market. With metal halide going away, lamps and ballasts are getting expensive and you can’t find them easily. For a community or school to go out and replace a lamp and ballast, it’s almost $5,000 just to get a lift truck.

LL: Do you hear objections about the cost of an LED system?

MB: We’ve done some calculations for the communities who ask, “Why would we go LED? We’re used to spending X per year and it’s in our budget for $25,000 a year for maintenance on the field lights.” So you look at that, and you look at the cost of one of these systems for a specific field – which, if it is a brand new system with controls, could cost $65,000 or $75,000 whereas a retrofit might be $20,000. We explain how we’re able to bring down that cost with utility incentives to make the new system almost the same as what they already budgeted in most cases.

We’ve also worked with some of those utilities to put on-bill refinancing together, so the community doesn’t have to come up with the capital expense; it’s basically a 0% loan on their electric bill.

LL: How does that work?

MB: With on-bill repayment (OBR), the utility looks at an opportunity for savings. They might have a large savings goal in the community, and field lighting might be part of that. Because of the benefit to both parties – the utility and the community – in taking it off the grid, they come up with a mutual agreement to put this on their electric bill and pay it that way. So, if their bill is normally $1,000 a month, they’re going to save $500 a month by going to LED with controls, and the bill will stay at $1,000 for six years. So they’ll still have the same bill, but they will have brand new lights and controls. It’s a mutually beneficial situation.

EC: We just did the city of Pawtucket. It started out with us looking at a couple of fields, but when we started talking about OBR, they told us to look at all of their fields. We did every single field in Pawtucket – and there were 22 of them – and they put it on OBR, plus there was rebate money available.

LL: Is it hard to find these kinds of rebates?

MB: When sports lighting comes up as a project for a community, no one ever looks at utility incentives. Because of our relationships with utilities in New England, we know they are struggling to find efficiency goals based on where the codes are going. I think utilities across the U.S. are going to start having more issues on the electrification side, and large savings projects like these help support the grid and help communities reduce blackouts and brownouts.

LL: How did the pandemic affect business?

EC: We stayed busy through the whole thing, especially since a lot of the jobs were outdoors.

MB: Actually, the pandemic started driving solutions for utilities to support programs like sports lighting to get communities outside, and to get kids active and not just sitting home all day. That definitely helped spur ideas for community events. There were a number of municipalities that installed sports lighting to start holding outdoor events like having local bands performing. It created opportunity for communities to come together and gave people some normalcy during COVID. It was great to be a part of that.

LL: How is business now?

MB: We go out and propose these projects, and they’re no-brainers for a lot of towns. They don’t have to go through the process of sitting and waiting. Fiscal budgets are done around July 1, so July 1 through Dec 31 is our go time. There is an ebb and flow based on sports schedules and, because of that, installation windows can be tough. Our sweet spot for installations tends to be between November and January 1 or the summer. From July 1 until Sept 1, we’re probably going to be doing 15 fields simultaneously with multiple crews. That’s the other side of this, we vet our install network to make sure we’re using people who know what they’re doing. We have a great install network of six to eight contractors who travel throughout New England and we have each one specialized in an area where we’re able to feed them those opportunities. And as the utility incentives start to grow, we have other partners in the ESCO channel that have been supporting the applications and the paperwork and can turnkey some of these jobs in areas where Ed and I can’t get to.

A lot of utilities are building their next three-year DPU plans right now. Every three years the utilities need to come up with what will be the new initiatives, and sports lighting is starting to become more prevalent and being added to these three-year plans.

LL: What else is on the horizon?

MB: We have an upcoming project in Georgetown, Mass., that is an interesting collaboration. We worked with Cooper Lighting on the fixtures and the Local 103 union and J & M Brown Co., are donating their time to do the lighting installation for two fields in the community. The town doesn’t have any lights, they had no budget, and no utility money, so this is a pretty big deal. Things like that are starting to come up. People want to do this for their communities and want to be engaged, and I think sports always brings people together and this is bringing something to the town, where they can also do concerts and events that everyone can enjoy.

We recently did a hockey rink for Sacred Heart University in Connecticut that was brand new construction. They wanted the lighting to pull the fans in, so we did color-changing and dynamic lighting effects and they liked it so much that we’re in the middle of doing that for their basketball court.

We’re seeing more and more manufacturers starting to look at sports lighting as an option in their product offering. The market is starting to change, and we’re just a little bit ahead of it.